METHODS OF HELIUM LEAK TESTING In principle two methods are applied for leak testing and localization of leaks, the "Vacuum method" and the "Overpressure method".

At the "Vacuum method" the object to be examined for leaks is evacuated and sprayed from the outside with a search gas, in this case Helium. The gas enters through any leaks present in the object and is detected by a sensor connected to the leak test instrument.

At the "Overpressure method" the object to be examined for leaks is filled with a search gas, Helium, under slight overpressure. The search gas escapes through any leaks present to the outside and is detected by a detector probe. This detector probe is in most cases called a "sniffer" acting as a gas sampling probe.

For both methods specially developed leak detectors are available.

The object under test should, if possible, be tested according to its final mode of use, i.e. if it is used under vacuum, the vacuum method should be applied, if it is finally pressurized, the overpressure method should be adopted.

Examples of testing with the two methods are illustrated below. The Vacuum method is illustrated with the Hood Test and the Tracer Probe Test and the Overpressure method with the Hood test, the Bombing test and the Detector Probe or Sniffer test.

Vacuum method - Hood test

The Hood Test is an overall leak test. The evacuated test object is covered with a (plastic) hood. The space between the test object and the hood is filled with Helium from the search gas reservoir so the total outer surface of the test object is exposed to the Helium search gas. The helium enters through all leaks present at the evacuated test object and thus the detector connected to it. The detector now indicates the total leak rate.

The hood test can for example be used for examination of small vessels.

g 2: Helium Leak Test, Vacuum Method, Hood Test

Vacuum method - Tracer probe test

At the tracer probe test the same set-up as used for the hood test is applied, but without the hood. A spray gun is used to spray a fine jet of helium search gas at areas suspected of leaking. Again the helium enters through leaks present at the evacuated test object and the detector connected to it. The detector indicates if a leak is present at the area the helium search gas is exposed to.

The tracer probe test can for example be used on seals, flange connections, weld seams etc..

g 3: Helium Leak Test, Vacuum Method, Tracer probe test

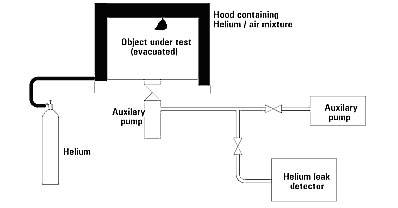

Overpressure method - Hood test

As in the vacuum hood test the overpressure hood test is an overall leak test. A test set-up similar to the vacuum test is used. A vacuum chamber is used for the hood, which can be evacuated by a auxiliary pump and to which the leak detector is connected. The helium search gas which is escaping through leaks in the test object is indicated by the leak detector.

The use of a helium leak detector allows detection of extremely small leaks and is suitable for automatic leak detection in industrial equipment.

The hood test can for example be used for examination of vessels, heat exchangers etc..

g 4: Helium Leak Test, Overpressure Method, Hood test.

Overpressure method - Bombing test

The bombing test is a pressure/vacuum method of leak detection used for testing of hermetically sealed components containing a cavity which can be gas-filled or evacuated. The objects to be tested, get in a pressure chamber exposed to the helium search gas. During an exposure time of up to several hours at a high helium pressure, the helium will penetrate through any leaks present in the test object. This is the part referred to as the "bombing". After the pressurisation or bombing the objects are tested for helium emission in a vacuum vessel, following the same procedure as in the hood test. This test permits detection of the smallest leak rates and is especially used for objects which can not be gas-filled by other means.

The bombing test can for example be used for examination of transistors, ampoules etc..

g 5: Helium Leak Test, Overpressure Method, Bombing test.

Overpressure method - Sniffer test

At this type of test the suspected areas of the test object are carefully explored by means of a detector probe, a "sniffer", which is connected to the leak detector. The object to be tested are under helium search gas overpressure. The sensitivity of the method of the method and the accuracy of localising any leaky points depend on the nature of the search gas, the design of the sniffer and the time constant of the actual leak testing device.

The sniffer test can for example be used for examination of vessels, heat exchangers, seals, flange connections, weld seams etc..

g 6: Helium Leak Test, Overpressure Method, Sniffer test.

Conclusion

To summarize, some of the capabilities of the Helium Leak Test are listed below.

- leak rates down to 10-10 mbar l / s can be detected

- both objects with vacuum or overpressure can be examined

- the objects can be examined during operation

- the examination can be performed fast and effective

- non poisonous, non explosive and inexpensive gasses are applied

- leaks can be detected in due time to prevent safety or operational hazards

- leaks can be detected in due time to prevent unplanned and expensive shut downs

LEAK RATE CONVERSIONS:

| |

Leak Rate |

| |

mbar x L/s |

std.atm.cc/s* |

torr x L/s |

Pa x L/s |

Pa x m3/s |

| 1 mbar x L/s |

1 |

0.987 |

0.75 |

100 |

0.1 |

| 1 std.atm.cc/s* |

1.013 |

1 |

0.76 |

101 |

0.101 |

| 1 torr x L/s |

1.33 |

1.32 |

1 |

133 |

0.133 |

| 1 Pa x L/s |

0.001 |

0.0987 |

0.0075 |

1 |

0.1 |

| 1 Pa x m3/s |

10 |

9.87 |

7.5 |

100.000 |

1 |

| |

Equivalent Leak Rates for Freon, Helium, and Air |

| |

std.atm.cc/s (air)* |

kg/h (air) |

mg/s (air) |

oz/year (air) |

g/year (freon) |

oz/year (freon) |

std.atm.cc/s (helium)* |

| 1 std.atm.cc/s (air) |

1 |

4.65 x10-3 |

1.292 |

1436.78 |

526.59 |

1.49*104 |

2.687 |

| 1 kg/h (air) |

215.06 |

1 |

0.0036 |

3.24*10-6 |

2.743*10-8 |

9.6756*10-10 |

577.849 |

| 1 mg/s (air) |

5.974 * 10-4 |

277.778 |

1 |

1.12 * 103 |

9.876 *10-11 |

3.4776 * 10-12 |

2.08 |

| 1 oz/year (air) |

6.96 *10-4 |

3.09 *105 |

8.93 *10-3 |

1 |

8.879 *10-11 |

3.126 *10-15 |

1.857 *10-3 |

| 1 g/year (freon) |

1.899 *10-3 |

3.645 * 107 |

1.0125 * 1010 |

1.1263 *1013 |

1 |

0.03527 |

5.1 *10-3 |

| 1 oz/year (freon) |

6.7 * 10-5 |

1.0335 * 109 |

2.8755 * 1011 |

3.1987 * 1014 |

28.3495 |

1 |

1.8 * 10-4 |

| 1 std.atm.cc/s

(helium)* |

0.3722 |

1.731 * 10-3 |

0.481 |

538.46 |

157497.2 |

5556 |

1 |